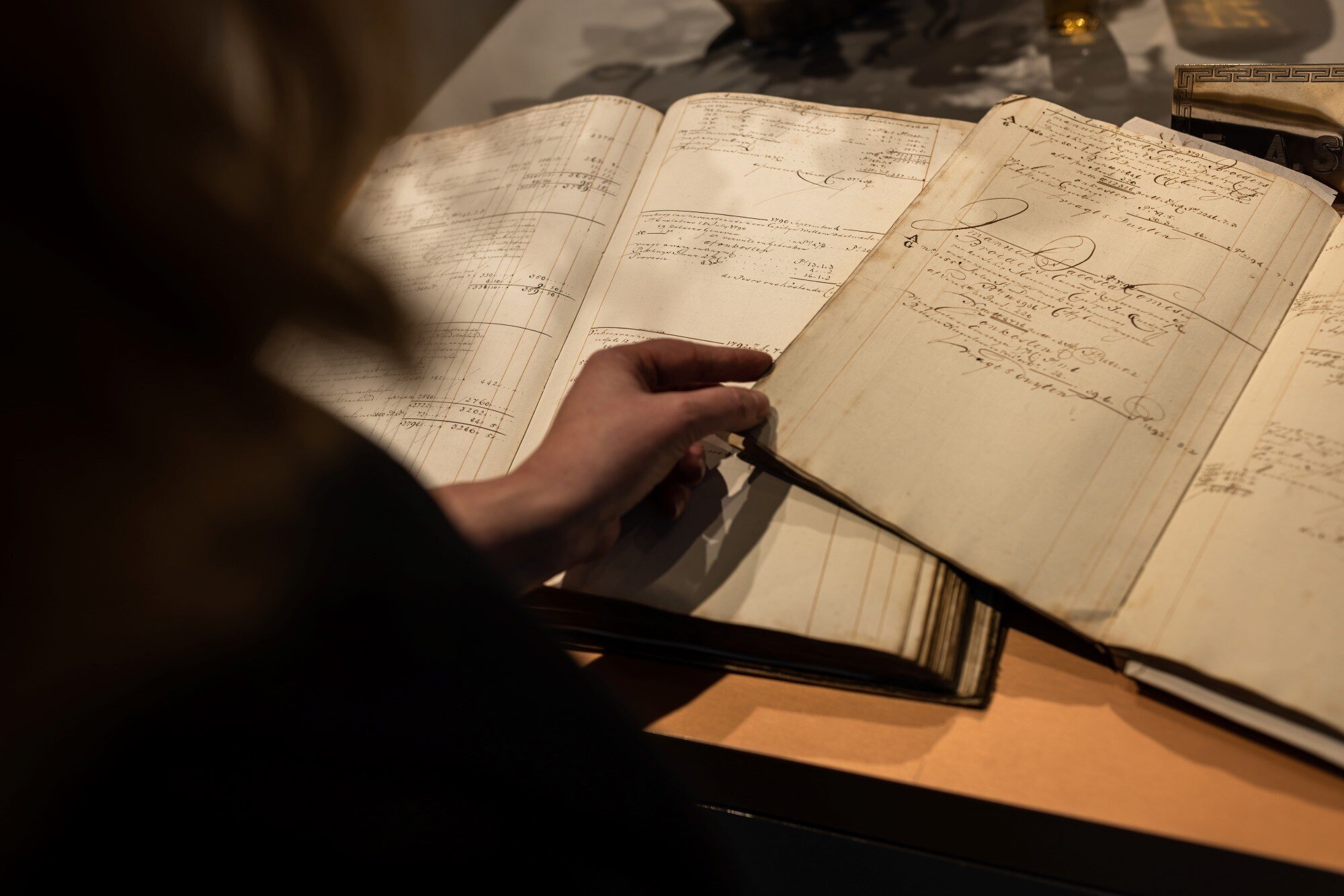

The Art of Rum Ageing

Rum is an interesting beverage that can be consumed fresh from the still but also aged to create new flavour profiles. The ageing process unfolds gradually, involving a series of changes and adaptations over several years. From the type of wood used to the charring process and other subtleties, ageing is an art form kept alive throughout the centuries by cellar masters and connoisseurs.

What is ageing?

In spirits production, ageing refers to the process of keeping liquor in a vessel for an extended period of time, allowing it to mature or develop complex flavours. During ageing, physical, chemical, or natural biological changes can occur as time passes.

In Rum, ageing typically involves storing the liquid in casks (barrels) for a prolonged period. The liquid becomes more concentrated and takes on extractives of various wood compounds, leading to enhanced flavour, aroma, and character. Ageing is commonly employed in Rum production, though not all Rum undergoes ageing. These types of Rum are called “unaged Rum”.

Learn more about the complete process of Rum production

Different techniques to age Rum

There are probably as many approaches to ageing Rum as there are Rum producers. Producers can determine the type of liquid and wood, the cask size, how much charring, and how much alcohol percentage they want to retain during ageing, among other factors. They often have their own technique and traditions, and no two distilleries are alike when it comes to ageing Rum. As such, there is a large diversity in how Rum is aged, which creates unlimited flavour profiles.

Cask/barrel ageing

The most common technique for ageing Rum is letting it sit for a long period of time in wooden barrels. Various species of oak and less common woods, e.g. chestnut, are used to age Rum. American oak is the most commonly used wood, though some distilleries can use French or European oak. Secondary ageing is employed to add extra dimensions to the spirits.

Cask size

Casks come in various sizes, typically from 200 to 500 litres. In the 18th and 19th centuries, Rum was often stored in 500-litre puncheons. Nowadays, the 200-litre barrel is the most common size. Other sizes include the hogshead (250 litres), butt (500 litres), and pipe (650 litres), which are commonly linked to wine, sherry, or port.

Wood selection

The type of wood from which a cask is made impacts the imparted flavours. Previously, casks were made from a wide variety of hardwoods, including sherry, acacia and chestnut. Brazil has many native hardwoods, including Jequitiba and Amburana, that impart unique flavours to cachaça.

However, oak is the dominant wood used today. You might see the following oak types the most in production.

- American oak: American oak grows in the eastern half of the United States. It is chosen for its widespread presence and sturdy structure, which can be effective at preventing liquid from leaking.

- European oak: European oak grows in much of western Europe. Some common subvarieties are French and Spanish oak. European oak is commonly more subtle in the flavours it imparts compared to its American counterpart. French oak is also popular in ageing Cognac and Rum, especially in French regions like Martinique and Guadeloupe.

Cask heat treatment

A cask will go through heat treatment before it is filled with Rum. These processes are known as toasting and charring. Toasting and charring can help release extra flavours and aromas and provide sanitation.

- Toasting: Toasting a cask exposes the inner walls to high heat without direct flame contact. Toast levels range from light to dark. Over several minutes to an hour, the wood's surface darkens as the compounds break down and the tannins within mellow. After toasting, the wood’s outermost surface develops a red layer, where all the converted vanillin and wood sugars reside. As Rum expands in and out of the wood during ageing, it absorbs the flavours from the red layer.

- Charring: The charring process is a more advanced way to toast a cask and release different flavour profiles. It involves burning the wood’s surface with a sustained open flame. There are different levels of charring, from 1 (light charring) to 4 (crocodile char). The technique creates a layer of charred wood that acts as a carbon filter to remove certain organic compounds in Rum. The red layer found in toasting now sits just below a char layer. When Rum is aged in a charred cask, it absorbs the red layer’s flavours while undergoing carbon filtration via the char layer. Compared to toasting, charring is quite quick.

Other forms of ageing

Solera ageing

Solera, or the Solera system, is an ageing technique commonly used by producers in the Spanish-style tradition. Originally from the Sherry industry, Solera is a customary practice for crafting various types of sherry. Solera combines Rums of different ages into layers within a series of barrels. Periodically, a small portion is withdrawn and bottled, while younger Rum is added to replenish the emptied space.

This perpetual process ensures that the youngest Rum continuously interacts with older, more mature Rum, resulting in a blend that embodies a harmonious balance of youthful vitality and aged complexity. Over time, this method imparts depth and richness to the final product, showcasing a Rum with nuanced characteristics derived from its youth and maturity.

Vatting

While most Rum ages in casks, some Rum makers use larger wooden vessels known as vats for some or all of their ageing. Vats are usually circular or oval shaped and range from a volume of 1000 litres to 20.000 litres and more. The larger the vat, the lower its ratio of inner surface area to liquid volume. Rum, through this way, has proportionately less contact with the wood. Thus, less extraction will occur.

Cask finishes

A cask-finished Rum first ages in its usual types of cask. e.g., ex-bourbon. The Rum is then transferred to a cask that previously held something else, such as port, wine, sherry, or calvados. Ex-sherry and cognac casks are a popular choice. This is called ''secondary ageing''.

These used barrels can enhance some flavours in Rum, contributing to the flavour formation process in Rum ageing. Moreover, the strict regulations in Bourbon or Whisky production mean used barrels cannot be recycled for the next batch of spirits. This creates a surplus of barrels that the Rum industry can reuse.

Stainless steel resting

Resting is not the same as ageing, though it is also a method to mellow out Rum and enhance its flavour. Rum is rested in stainless steel tanks for a certain period of time, during which the flavour compounds can separate and rejoin to create a smoother liquid. Stainless steel doesn’t impart any additional aromas or flavours in the Rum, making it a good medium for Rum to mature.

Continental Ageing and Ageing at Origin

When it comes to ageing, there can be two separate methods categorised by where the Rum is aged. These are namely Continental Ageing and Ageing at Origin.

Continental Ageing

Continental Ageing refers to the process of maturing Rum in the European climate, which is distinct from the tropical conditions where most Rum was initially distilled. The climates in Europe are typically cooler and more temperate, with fewer temperature fluctuations and less humidity.

This method of maturing slows the interaction between the Rum and lowers the evaporation rate in the barrel, creating a gradual maturation process. Cooler temperatures lead to less evaporation (called ‘angel’s share’) and a more controlled ageing environment. This potentially preserves the Rum's subtleties, complexities and characteristics as they were originally distilled. It is worth noting that in these conditions, the bulk volume and alcohol percentage decrease together over long periods of time.

Ageing at origin

Ageing at Origin, commonly categorised as ‘Tropical Ageing,’ occurs in tropical climates where most Rums are distilled. The hot and humid conditions accelerate the ageing process, increasing the interaction and compound exchange between the Rum and the oak barrels. This faster maturation extracts more flavours from the oak more quickly than continental ageing.

The higher temperatures also increase the angel’s share, concentrating the flavours further. It is worth noting that in these types of conditions, the water within the distilled Rum will generally evaporate quicker and leave a higher alcohol percentage than when 1st filled.

Both methods offer distinct advantages, providing Rum enthusiasts with a variety of tasting experiences. Continental ageing and ageing at origin each contribute to the diversity of Rum, allowing for a broad spectrum of flavours and profiles to be enjoyed.

By using Rums that have been aged at origin for a short period of years and transferring them to the continent, producers can age the Rums for much longer maturation cycles without over-extraction of the oak compounds.

What happens to Rum during the ageing process?

Ageing happens slowly over time. During ageing, various chemical and physical processes can take place.

Chemical absorption

Rum’s prolonged exposure to the barrel can cause the wood to release some naturally occurring chemical compounds (extractives), which the liquid can absorb. These are typically cellulose, hemicellulose, lignin, or oak tannins.

Esterification

In simple terms, esters are the “flavour compounds” in Rum. They are organic compounds made up of alcohol and acid molecules that carry certain scents and flavours with them in the finished product. Esterification can happen during the fermentation process and the ageing process. During ageing, some esters may break apart. Thanks to the prolonged rest Rum gets during ageing, some of these esters may even come together to form other long-chain ester structures. Oxidation and evaporation.

Due to the wood's structure, there can be room for air to enter the liquid and for the liquid to evaporate from the barrels. Air ingress, known as the oxidation process, can promote the mellowing of the Rum and esterification. During ageing, evaporation can also occur naturally. The evaporated Rum is colloquially known as “angel’s share.” Fortunately, evaporation can eventually slow down after some time, but you can expect a bit less Rum after ageing compared to the original volume.

How long is Rum aged in a barrel?

The ageing duration varies across different types of Rum. Some Rum types go through little or no ageing, such as unaged Rum, while others can spend up to a decade or more in a cask.

Ageing practices also differ per producer. Some distilleries age their Rum anywhere between 6 months to 6 years, and others at 5 to 7 years, and so on. It is important to underline that the ageing duration for Rum depends on many factors, such as the temperature/micro-climate, the region, the local traditions, and the desired product.

The older the Rum, the better it is?

Some people associate the age of the Rum to its quality. However, this is not always the case since many different factors can affect the ageing process. For example, consider the different climate conditions in Jamaica and Liverpool. Rum aged for 12 years in Jamaica will be very different from Rum that spent the same duration in a cask in Liverpool. The same can be said about same-aged Rum coming from different wooden barrels. Therefore, a Rum’s age does not fully represent its quality, and vice versa.

Quality in Rums is generally subjective and personal to whoever tastes it, and particular profiles will relate to some more than others. What one individual likes will differ from another, though this is the beauty of Rum. The variety of Rums produced using different raw materials, employing different fermentation and distillation methods coupled with ageing in different ways, offers a wide range of flavour profiles to the end consumer when the distillates are bottled.

Purchasing aged Rum in bulk and more

Rum is becoming a popular spirit, not just in the spirits and cocktail industry but also in the confectionery and flavour/fragrance industry. Buying Rum in bulk to support different business operations is also increasing in demand. Finding trusted, continuous, and quality bulk Rum sourcers is also a top priority for decision-makers.

E&A Scheer specialises in sourcing and supplying bulk Rum all over the world. Together with our clients, we have been producing quality tailor-made Rum blends for business clients for over three centuries. With a consistent profile, quality, and character, E&A Scheer is a trusted partner for your Rum business.

We invite you to discover how we can help your business thrive. We can help you produce any Rum blend from aged or unaged Rum, light and dark Rum, or anything in between. With our sister company, The Main Rum Company, we also supply unique, old, rare, and aged Rum in casks.

Frequently asked questions

Can you age your own Rum?

Yes, you can age your own Rum. However, patience and understanding of the ageing process are required to achieve desirable results. Moreover, be aware of the regulations and dangers of storing alcohol in your country/region.

Does Rum get better with age?

Rum does not continue to age or improve once it has been bottled. Its ageing process occurs in barrels, where it develops its flavours and character. Once bottled, the ageing process halts, and the Rum maintains its taste profile without further maturation. However, the environment in which the bottle is stored can affect the Rum's condition over time, but it won't improve or age like wine in a bottle.